Wafer-Scale Fabrication of Hierarchically Porous Silicon and Silica by Active Nanoparticle-Assisted Chemical Etching and Pseudomorphic Thermal Oxidation

Abstract

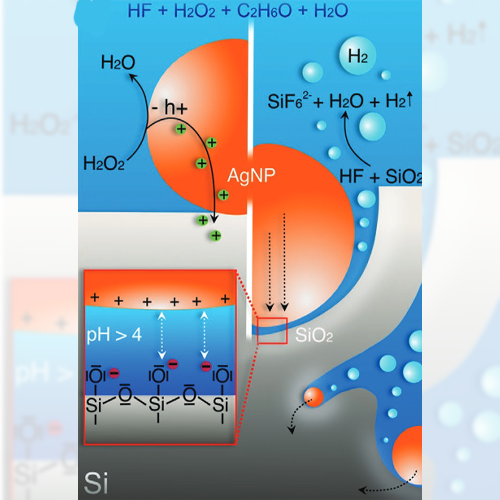

Many biological materials exhibit a multiscale porosity with small, mostly nanoscale pores as well as large, macroscopic capillaries to simultaneously achieve optimized mass transport capabilities and lightweight structures with large inner surfaces. Realizing such a hierarchical porosity in artificial mate-rials necessitates often sophisticated and expensive top-down processing that limits scalability. Here, an approach that combines self-organized porosity based on metal-assisted chemical etching (MACE) with photolithographically induced macroporosity for the synthesis of single-crystalline silicon with a bimodal pore-size distribution is presented, i.e., hexagonally arranged cylin-drical macropores with 1 μm diameter separated by walls that are traversed by pores 60 nm across. The MACE process is mainly guided by a metal-cata-lyzed reduction–oxidation reaction, where silver nanoparticles (AgNPs) serve as the catalyst. In this process, the AgNPs act as self-propelled particles that are constantly removing silicon along their trajectories. High-resolution X-ray imaging and electron tomography reveal a resulting large open porosity and inner surface for potential applications in high-performance energy storage, harvesting and conversion or for on-chip sensorics and actuorics. Finally, the hierarchically porous silicon membranes can be transformed structure-con-serving by thermal oxidation into hierarchically porous amorphous silica, a material that could be of particular interest for opto-fluidic and (bio-)photonic applications due to its multiscale artificial vascularization.

Explore Further

Full Article: